Choosing the right asset and inventory management software can be the difference between a sold-out seasonal collection and excess stock gathering dust. For fashion brands navigating complex size and color variations, multiple sales channels, and intricate returns processes, a powerful system is essential. The right software prevents overselling, streamlines order fulfillment, and ultimately protects your profit margins.

This guide will walk you through five crucial criteria for evaluating these systems. We’ll cover variant-focused SKU tracking, precise integration flows between platforms like Shopify and QuickBooks, apparel-specific reverse logistics, and transparent ROI modeling for growing brands. Let’s dive into how you can effectively compare vendors and confidently select a solution that fits your business needs.

What is Asset and Inventory Management Software for Fashion?

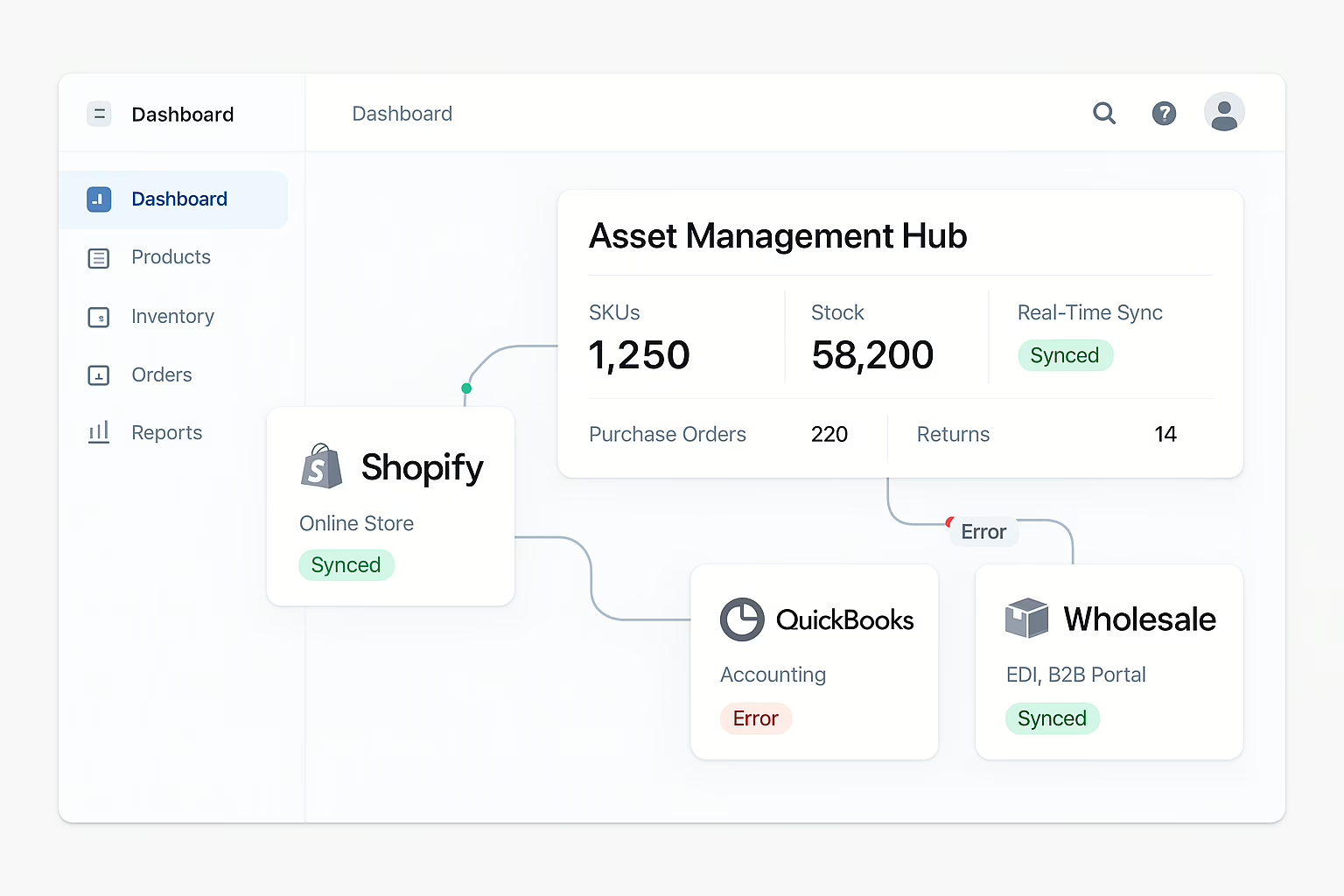

Asset and inventory management software for the fashion industry provides a centralized “brain” for your entire operation. It combines real-time SKU tracking with management for physical assets like showroom samples. By syncing data from Shopify, wholesale portals, and third-party logistics (3PL) providers, it offers a single, accurate view of available-to-promise (ATP) inventory across all channels. This ensures your sales, operations, and merchandising teams are working from the same information, preventing stockouts and maximizing sales opportunities.

Key Capabilities to Expect

A robust system should offer real-time ATP visibility, unique UPCs for every item variant, and support for barcode or RFID scanning. It must also include features for managing cycle counts, processing returns, handling purchase orders, and generating reports that connect inventory data to your cost of goods sold (COGS) and profit margins.

- Did you know? Implementing regular cycle counts can reduce inventory variance by 15–25%.

- Pro Tip: Barcode scanning, when paired with solid processes, has an error rate of less than 0.1%.

Master the Complexity of Apparel SKUs

For apparel brands, managing inventory goes beyond simple item counts. The foundation of an effective system is its ability to handle products at the variant level. This means the software sees a master style not as one item, but as a collection of individual variants for each size, color, season, and pack configuration. Forecasting and reordering must happen at this granular level to prevent inaccurate purchasing and listing errors.

Size/Color Matrices and Variant Barcodes

Your software must support detailed size and color matrices, assigning a unique Universal Product Code (UPC) or Amazon Standard Identification Number (ASIN) to every single variant. This is critical for accurate listing on platforms like Shopify, as it prevents the creation of duplicate SKUs that can disrupt inventory counts and sales data.

Bundles, Kits, and Pre-Packs

Many fashion brands sell products as bundles or pre-packed kits. Your inventory system should manage these effectively. For example, when a customer returns a kit, the software should automatically de-kit the items, returning the individual components to your saleable stock. This requires forecasting at both the kit and component levels to ensure accurate stock management.

Unify B2C and Wholesale Channels

Modern fashion brands often sell through both direct-to-consumer (B2C) channels like Shopify and business-to-business (B2B) wholesale channels. A unified asset and inventory management software allows you to run both from a single pool of inventory. You can reserve stock for key wholesale accounts, manage different price lists, and track purchase order commitments without the risk of double-selling items. This consolidated approach keeps financial reporting clean and gives your team a single source of truth.

- Insight: A unified Order Management System (OMS) can lift order fill rates by 3–5%.

B2C: Shopify and Marketplace Sync

For your consumer-facing channels, the software should sync seamlessly with e-commerce platforms and marketplaces. This includes features like placing holds on inventory when a customer adds an item to their cart and managing partial order releases for pre-orders or backorders.

B2B: Wholesale Portals and Purchase Orders

On the wholesale side, the system must support integrations with B2B platforms like JOOR or NuOrder, allowing you to ingest purchase order data. It should also enable customer-specific price lists and payment terms, streamlining your wholesale operations from order to fulfillment.

The Integration Blueprint: Connecting Your Tech Stack

A smooth operational flow depends on clean integrations between your key systems. A typical and effective blueprint for a fashion brand connects Shopify, your inventory management system (IMS), a shipping platform like ShipStation, your 3PL, and accounting software like QuickBooks.

The process should look like this:

- Orders are captured in Shopify.

- The order data flows to the IMS, which serves as the master record for inventory and SKUs.

- The IMS sends fulfillment requests to ShipStation or a 3PL based on predefined routing rules.

- ShipStation generates shipping labels and sends tracking information back to the IMS.

- The IMS updates the order status and sends financial data (revenue, COGS) to QuickBooks, which updates the inventory asset value.

Setting clear “sources of truth” is vital before connecting these systems. For instance, the IMS should be the master for SKU data, while Shopify is the source for order data. This prevents data conflicts and ensures accuracy.

Designing a Smart Returns Process for Apparel

Returns, or reverse logistics, are a significant part of the apparel business. An efficient returns process can recover value and provide crucial insights. Your software should support a clear workflow for managing returned merchandise, from initiating a Return Merchandise Authorization (RMA) to inspecting and restocking the items.

RMA Routing and Condition-Based Rules

Integrations with platforms like Loop Returns can allow customers to initiate returns themselves. Once an item is received, your team can inspect it and assign a condition grade (e.g., A for “like new,” B for “minor defects”). Based on this grade, the system should automatically route the item to be restocked, reworked, or designated for an outlet or donation.

Metrics That Matter

Tracking key metrics is essential for improving your returns process. Focus on:

- Recovery Rate: The percentage of value recovered from returned goods.

- Time-to-Restock: How quickly an item is made available for resale.

- Reason Codes: The reasons customers provide for returns, which can highlight issues with product fit, description, or quality.

Calculating the ROI for Your Investment

For brands with revenue under $20 million, understanding the total cost of ownership (TCO) and potential return on investment (ROI) is key. When requesting quotes, ask for an itemized breakdown of subscription fees, integration costs, and implementation charges.

A powerful inventory system often pays for itself within months. By reducing stockouts by 20–40% and cutting picking and packing labor by 20–30%, the efficiency gains translate directly to your bottom line. Model a simple ROI calculation using your average order volume, average order value, and labor rates to build a business case for the investment.

Final Thoughts

Effective asset and inventory management software is built on a variant-first data model, a unified view of inventory across all channels, and seamless integrations. By focusing on real-time data sync, granular forecasting, and disciplined returns management, fashion brands can significantly reduce stockouts, lower operational costs, and improve financial accuracy. When evaluating solutions, prioritize those that offer a clear implementation plan and can scale with your brand as it grows.