Tired of stockouts, overbuys, and late-night spreadsheet fixes?

If you’re scaling a fashion brand under $20M, the cost of inventory management software can feel fuzzy—until backorders, markdowns, and chargebacks make the price of doing nothing crystal clear. This guide turns cost into ROI so you can invest with confidence.

Modern tools can streamline your operations, sync inventory across channels, and give you the control you need to scale efficiently. Below, we break down the cost of inventory management software, total cost of ownership (TCO), the features that actually move the needle, and a simple model to prove payback.

Quick answer (for skimmers): Most sub‑$20M fashion brands spend $300–$2,500/month for SaaS IMS and $1,500–$6,000+/month for WMS/ERP. Year‑1 TCO typically lands 1.5–3× higher than steady‑state subscription due to implementation, integrations, data cleanup, training, and hardware.

The Problem (in plain English)

Fashion margins are thin and demand is spiky. Overselling frustrates customers, underselling ties up cash, and manual reconciliation steals time from growth. Disconnected DTC, marketplace, POS, and B2B wholesale channels create blind spots that lead to stockouts, overstock, and mounting carrying costs.

Why this matters: Every delay in inventory sync, every mis-pick, and every slow return compounds. You lose sales now and pay again later through markdowns and lower lifetime value.

What Actually Drives Cost for Fashion Brands

Pricing scales with operational complexity. Key drivers:

- Order volume & channel mix: DTC, marketplaces, retail, and B2B wholesale

- SKU complexity: style–color–size variants, pre‑packs, size runs, drops

- Returns rate & workflows: RMAs, instant exchanges, return‑to‑stock speed

- Fulfillment model: in‑house, 3PL, or distribution center (multi‑warehouse)

Simple catalog example: A small DTC label with ~1,200 SKUs adds minimal setup cost.

Complex catalog example: A seasonal brand with 1,000 styles × 12 colors × 8 sizes needs extensive variant mapping and rules—often 30–50% more implementation effort than a 1k‑SKU catalog.

Pricing Models & Typical Ranges

Know exactly how you’re billed and what’s included. Common structures: SaaS tiers, per‑user, per‑location, per‑order, or hybrid. WMS/ERP licenses and 3PL integrations add layers.

- Blastramp HQ starts at about $750/month.

- Blastramp WMS starts from $1,500/month.

Add‑ons that often apply to small brands:

- EDI: $200–$800/month

- Returns portals: $100–$400/month

- Per‑order overages: $0.05–$0.20 beyond included volume

Micro‑example: A brand processing 5,000 orders/month with EDI + returns should budget $1,200–$2,500/month.

Feature Cost Multipliers (and Why They’re Worth It)

Some modules raise monthly spend—but usually create outsized ROI:

- Real‑time multi‑channel inventory sync & allocation (oversell prevention)

- Advanced returns & exchange workflows (faster resale, happier customers)

- EDI (clean retailer compliance, fewer chargebacks)

- Demand planning/MRP (lower overstock and stockouts)

- WMS wave/batch/slotting (picking accuracy and speed)

- Multi‑warehouse orchestration (DC + 3PL + stores)

Typical ranges:

- Demand planning: $400–$1,500/month

- WMS wave/batch: $300–$1,200/month

Micro‑example: Demand planning might lift a plan from $1,200 → $2,400/month; a 10% overstock reduction can repay that in weeks.

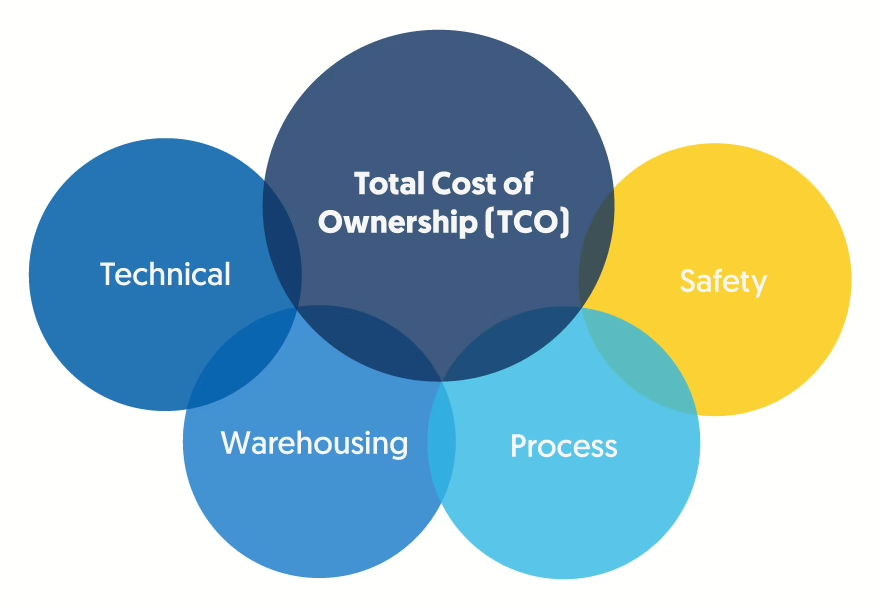

TCO: Beyond the Subscription (Year‑1 vs. Years 2–3)

Your first‑year TCO almost always exceeds the subscription price.

Budget the full picture:

- Onboarding & implementation: $5,000–$25,000 (4–12 weeks; assign a project lead ~10–20 hrs/week during go‑live)

- Data migration & cleansing: $2,000–$10,000 (often lowers error rates 20–40%)

- Integrations & middleware: $1,000–$5,000 per system (5–15% annual maintenance)

- Training & change management: $1,000–$5,000 (expect a 1–2 week productivity dip)

- Support & overages: Premium support +10–20%; extra environments $100–$300/month

- Hardware & labeling: scanners $300–$800; label printers $250–$600

Rule of thumb: Year‑1 TCO = 1.5–3× steady subscription. Model 3–5% annual inflation and hardware depreciation after stabilization.

Simple formula:

Year‑1 TCO = Subscription + Implementation + Migration + Integrations + Training + Hardware + Support + Overages

Budget checklist:

- Request line‑item quotes + detailed SOW

- Confirm SLAs, usage caps, sandbox access

- Schedule a dedicated data cleanup phase

Features That Move the Needle (Fashion‑Specific ROI)

- Real‑time multichannel sync: 5–10% fewer stockouts in 60–120 days

- Returns & instant exchanges: 20–40% faster return‑to‑stock

- POs, case‑packs, pre‑packs (wholesale): 30–60% fewer chargebacks; 5–10 warehouse hours saved weekly

- Fulfillment/WMS accuracy: wave/batch can raise picking accuracy from 98.5% → 99.5%

- Demand planning: +10% forecast accuracy → 8–15% carrying‑cost reduction

How to Calculate ROI (Keep it Practical)

Annual Benefit = Revenue Uplift + Cost Savings

ROI = (Annual Benefit − Annual Cost) ÷ Total Cost

Payback (months) = Total Cost ÷ Monthly Benefit

Track these drivers: stockout reduction, labor‑hour savings, carrying cost reductions, sell‑through/markdown avoidance, returns processing speed, shrink/chargeback prevention.

Worked examples:

- Omnichannel DTC (~$10M revenue):

Stockouts 7% → 4% (~$25k/mo recaptured revenue @ 55% margin = $13.8k gain), 0.5 FTE saved (~$2.5k/mo), carrying cost −$8k/mo → ~$24k/mo total benefit vs. $3k/mo software. Payback < 4 months. - Wholesale‑heavy (~$15M revenue):

EDI errors −60% (chargebacks −$8k/mo), case‑pack automation (+80 DC hrs/mo @ $25/hr = $2k), reship −$1.5k/mo → ~$11.5k/mo benefit vs. $5k/mo cost. ~130% Year‑1 ROI.

Reality check: If stockouts drop 2–3 pts and carrying costs fall 5–8%, most sub‑$20M brands break even within six months.

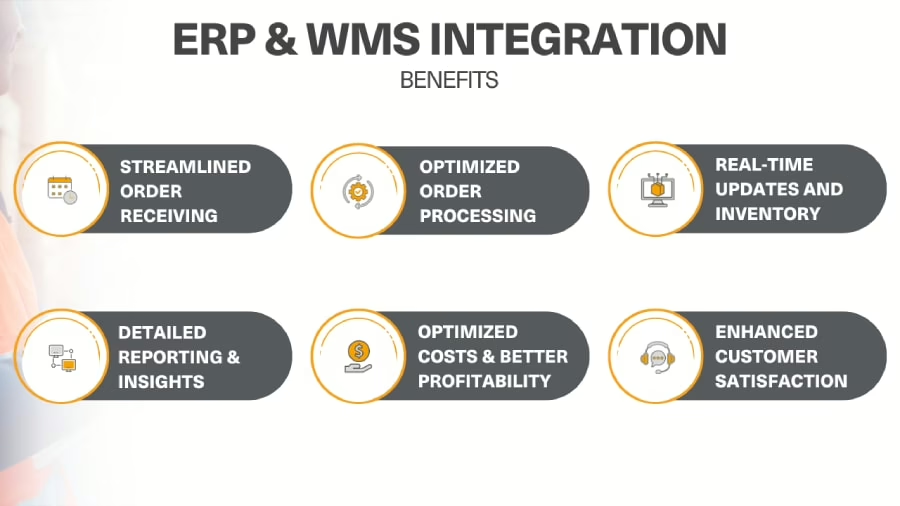

Deployment Fit: SaaS vs. WMS/ERP vs. 3PL

Choose based on process fit—not hype.

When SaaS IMS wins (most sub‑$20M brands):

- <100k orders/year; 1–3 locations; DTC + light wholesale; manageable returns

- Time‑to‑value 4–8 weeks and fastest path to positive ROI

- Blastramp HQ aligns well for this stage

When WMS/ERP is justified:

- 200k orders/year, complex EDI, multi‑entity finance, waves/slotting, multi‑DC

- Higher upfront/ongoing costs and heavier change management

3PL integrations (grow without capex):

- Fast geographic scale; per‑order fees $0.05–$0.20

- Clarify responsibility for EDI handoffs to avoid silent margin leaks

Real‑World, Transparent TCO Examples (Sub‑$20M)

- $5M DTC apparel: $750/mo + $12k setup → stockouts −4 pts; ~⅓ FTE saved; ~7‑month payback

- $12M omnichannel + 3PL: $1,800/mo + $18k integrations → EDI accuracy +50%, margin +1.2 pts

- $18M DTC/wholesale with EDI: $3,200/mo + $25k EDI setup → chargebacks −50%, DC labor −60 hrs/week

A Practical Stack Blueprint (<$20M)

Start lean, expand in phases:

- SaaS IMS (e.g., Blastramp HQ) + Shopify

- Add marketplace connectors, POS, QuickBooks, ShipStation

- Layer returns (Loop), wholesale (Joor/NuOrder/Brandboom)

- Add demand planning once data is stable

Expected spend: $750–$2,500/month on software; $20k–$60k in Year‑1 including implementation, migration, integrations.

Budgeting & Vendor Comparison: What to Ask

- API limits, data ownership, uptime SLAs, sandbox access, roadmap

- Who maintains integrations? Are overages capped? Any annual prepay discounts?

- Negotiate milestone‑based payments and clear exit clauses

Pro tip: Offer a transparent TCO sheet and a fashion‑specific ROI calculator during evaluation—it builds trust and speeds decisions.

Common Pitfalls (and Easy Fixes)

- Over‑buying modules you won’t use → Run a phased rollout; add only by exception

- Messy product data → Schedule a cleanup sprint before migration

- Ignoring returns workflows → Stand up RMAs/instant exchanges early

- 3PL vs. EDI finger‑pointing → Define RACI and SLAs up front

- Under‑estimating change management → Train roles; create SOPs; expect a short dip

90‑Day Measurement Plan (Post‑Go‑Live)

Track monthly at an exec cadence:

- Stockouts, order accuracy, pick rate

- Return‑to‑stock time, aged inventory, markdown %

- Labor hours per 1,000 orders; chargebacks; shrink

Use these trends to tune allocations, reorder points, and workflow settings.

Ready to See It in Your Numbers?

Model your stack with Blastramp and validate payback in a short pilot. Explore integrations, stress‑test inventory sync across channels, and quantify ROI before you commit.

Next step: Book a demo to build your TCO & ROI model with your real data.