Your warehouse just confirmed they shipped an order that’s been sitting in someone else’s shopping cart for the past hour. Meanwhile, your wholesale buyer is asking why their pre-booked inventory suddenly disappeared. Sound familiar?

For fashion brands juggling multiple sales channels, these inventory nightmares aren’t just frustrating—they’re expensive. Every oversell damages customer trust. Every missed wholesale order strains partnerships. Every delayed return ties up cash that could fund your next collection.

The real challenge isn’t finding inventory stock management software with endless features. It’s finding a system that actually understands how fashion brands work—one that handles your size runs, manages wholesale alongside retail, and keeps your inventory accurate whether you’re selling through Shopify, marketplaces, or B2B portals.

Why Fashion Brands Need Specialized Inventory Management

Generic inventory systems treat all products the same. But your vintage-wash denim in sizes 24-32 isn’t the same as selling widgets. Fashion inventory comes with unique complexities that can make or break your operations:

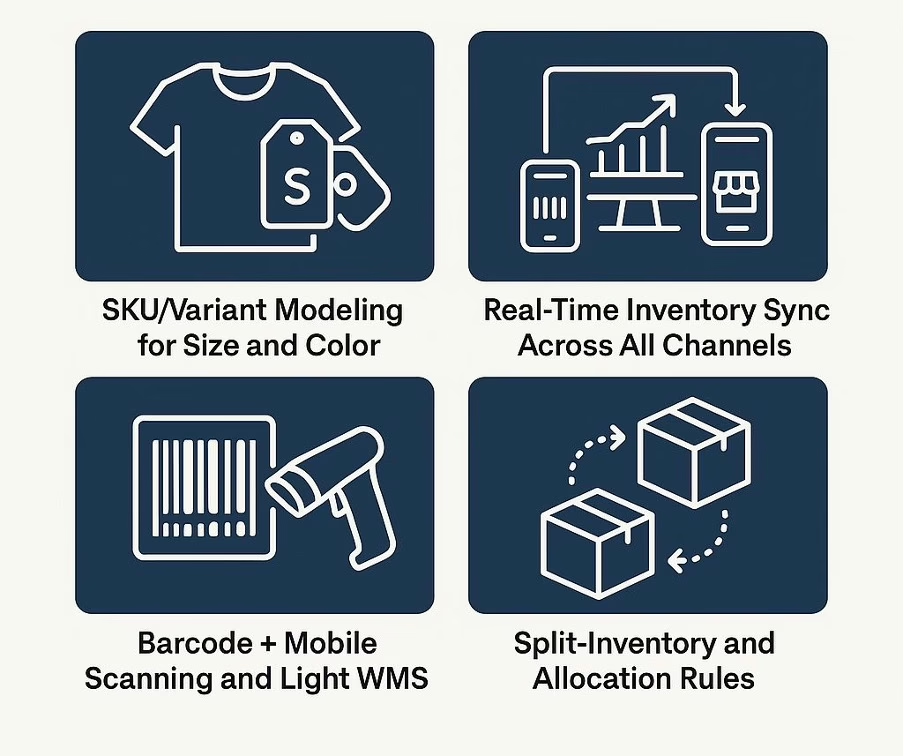

The Variant Challenge: A single style explodes into dozens of SKUs across sizes and colors. One dress becomes 20+ individual inventory items that need tracking, syncing, and allocation across channels.

The Channel Juggle: Your inventory lives everywhere—your website, wholesale showrooms, Amazon, your 3PL warehouse, items in transit, and returns being processed. Without real-time sync, you’re essentially flying blind.

The Speed Requirement: Fashion moves fast. A product drop can generate hundreds of orders in minutes. If your inventory sync takes 15 minutes to update, you’ve already oversold.

Understanding the Building Blocks of Fashion Inventory Control

Before diving into software features, let’s clarify what effective inventory stock management software actually does for your fashion brand:

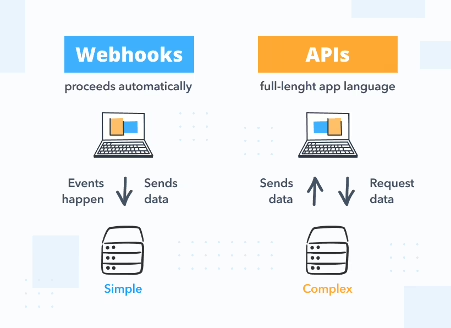

Real-Time Synchronization: Your Single Source of Truth

Imagine this: A customer buys your last medium sweater on Shopify at 2:47 PM. By 2:48 PM, that same sweater should show as unavailable on Amazon, your wholesale portal, and every other channel. That’s real-time sync.

Without it, you’re managing apologies instead of orders. Strong systems use webhooks (instant notifications) rather than polling (checking every few minutes) to maintain accuracy even during flash sales.

Smart Allocation: Protecting Revenue Across Channels

Not all sales channels are equal. Your wholesale partners might need guaranteed inventory for their pre-books. Your website needs stock for that upcoming influencer collaboration. Amazon requires buffer stock to maintain your seller rating.

Allocation rules let you split inventory intelligently. Set aside 60% for DTC launch, 30% for wholesale, and keep 10% as buffer stock. When one channel underperforms, smart systems can automatically reallocate to where demand is strongest.

Variant Management: Taming the Size Curve Beast

A single product launch might include:

- 5 colors

- 8 sizes per color

- Pre-packs for wholesale (2-2-2-2-1-1 size runs)

- Individual units for e-commerce

That’s 40+ SKUs from one design, plus different packaging configurations. Proper inventory stock management software models these relationships, letting you see both total style quantities and individual size availability at a glance.

The Hidden Costs of Disconnected Inventory

Before investing in new software, understand what poor inventory management actually costs your fashion brand:

Direct Revenue Loss: A 2% oversell rate on $5 million in annual sales means $100,000 in lost revenue—not including the customer lifetime value you sacrifice through poor experiences.

Labor Drain: Your team spends hours reconciling inventory across spreadsheets, manually updating wholesale availability, and investigating discrepancies. That’s expensive talent focused on tasks software should handle.

Margin Erosion: Delayed returns processing means products sit in limbo instead of getting back to sellable stock. During peak season, a 5-day return delay could mean missing the entire sales window for seasonal items.

Growth Barriers: Manual processes that work at $2 million in sales completely break at $10 million. Without scalable systems, growth becomes painful rather than profitable.

Building Your Fashion-First Inventory Stack

The most successful fashion brands under $20 million typically follow this technology progression:

Stage 1: Foundation ($1-3M Revenue)

Start with core inventory stock management software that handles:

- Multi-channel sync between Shopify and one marketplace

- Basic variant tracking

- Simple purchase order management

- Returns processing

Focus on accuracy over advanced features. Getting your inventory counts right across channels is worth more than complex forecasting at this stage.

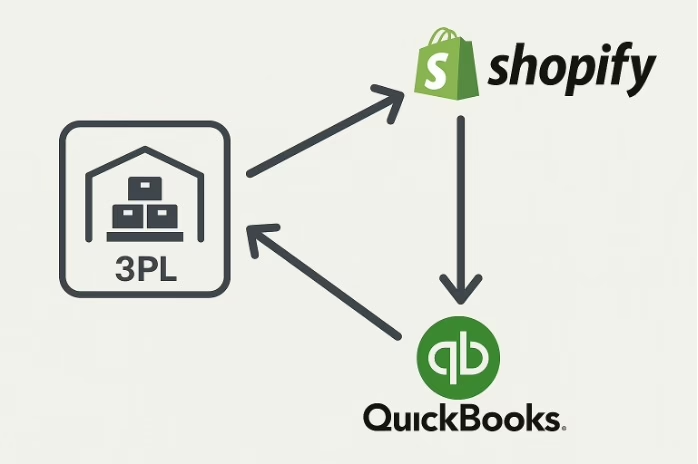

Stage 2: Acceleration ($3-8M Revenue)

Add capabilities as complexity grows:

- B2B wholesale portal for buyer access

- 3PL integration for automated fulfillment

- Barcode scanning for warehouse accuracy

- Allocation rules for channel management

This is where the right system becomes a competitive advantage, letting you take on more channels without adding proportional overhead.

Stage 3: Optimization ($8-20M Revenue)

Layer in advanced tools:

- Multi-warehouse orchestration

- EDI for major retail partnerships

- Demand forecasting by size curve

- Automated replenishment triggers

Here, your inventory system becomes the operational backbone that enables efficient scaling.

Practical Features That Drive Real Results

Let’s move beyond feature lists to understand what actually impacts your daily operations:

Wholesale and Trade Show Excellence

Your sales rep is writing orders at a trade show. With proper inventory stock management software, they can:

- Check real-time availability on their tablet

- Reserve inventory instantly to prevent double-booking

- Offer substitutions when specific sizes are low

- Process deposits to lock in orders

No more returning from market week only to discover you’ve oversold your entire spring collection.

Returns That Don’t Kill Margins

Returns are inevitable in fashion—industry averages run 20-30% for e-commerce. But they don’t have to destroy profitability. Automated returns management means:

- Items get graded immediately (A-grade back to stock, B-grade to outlet)

- Exchanges process without manual intervention

- Refunds trigger only after inspection

- Inventory updates instantly once items are restocked

A fashion brand processing 500 returns monthly can save 40+ hours of manual work through automation.

3PL Orchestration Without the Headaches

Working with fulfillment partners? Your inventory stock management software should:

- Route orders to the optimal warehouse based on geography and inventory

- Send advance shipping notices (ASNs) to speed receiving

- Track performance against SLAs

- Handle split shipments automatically

When done right, customers get faster delivery while you reduce shipping costs.

Red Flags: When Your Current System Is Holding You Back

How do you know it’s time to upgrade? Watch for these warning signs:

The Daily Scramble: Your morning starts with checking multiple systems to understand what you actually have available to sell.

The Wholesale Worry: You’re hesitant to take on new wholesale accounts because managing their inventory needs feels impossible.

The Growth Ceiling: You’re turning down opportunities—a new marketplace, a retail partnership—because your systems can’t handle the complexity.

The Margin Mystery: You can’t quickly answer “What’s our true inventory value?” or “Which SKUs are killing our cash flow?”

If any of these resonate, your current setup is actively limiting growth.

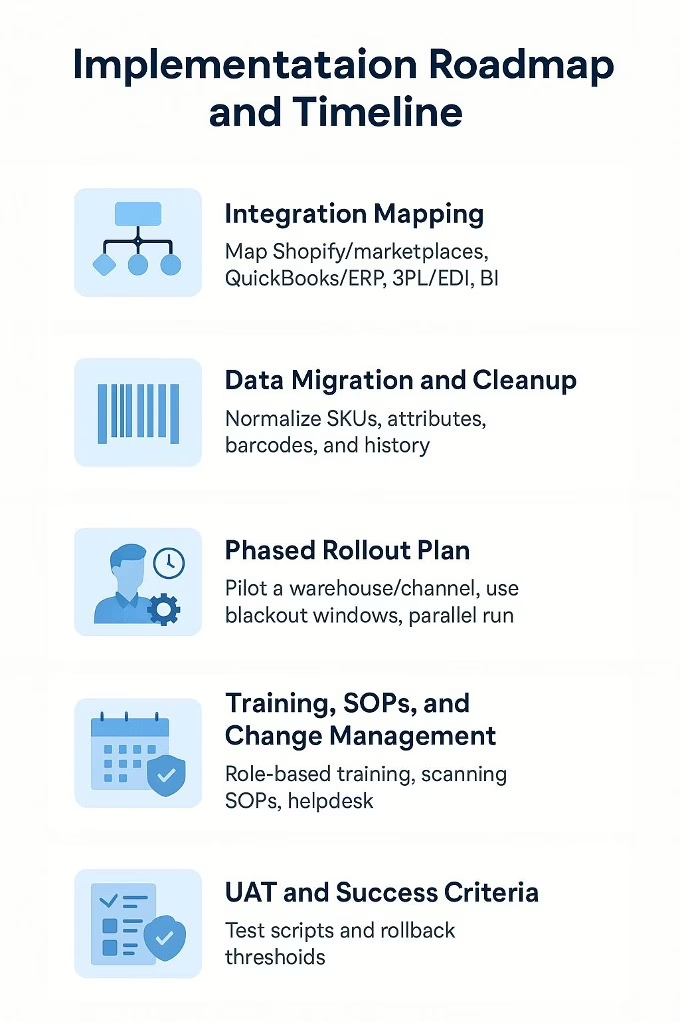

Implementation: Your Roadmap to Success

The difference between successful and painful implementations often comes down to approach:

Week 1-2: Foundation Setting

- Map all current sales channels and integrations

- Clean your product data (consistent sizes, colors, SKUs)

- Document current workflows and pain points

- Set clear success metrics

Week 3-4: Pilot Launch

- Start with one channel or warehouse

- Run parallel with old systems initially

- Train power users who become internal champions

- Document issues and refine processes

Week 5-8: Gradual Expansion

- Add channels one at a time

- Migrate wholesale partners in batches

- Implement advanced features gradually

- Monitor metrics and optimize

Week 9-12: Full Optimization

- Retire legacy systems

- Implement automation rules

- Set up reporting dashboards

- Plan for peak season scenarios

Measuring Success: KPIs That Matter

Track these metrics to quantify your inventory stock management software ROI:

Oversell Rate: Should drop below 0.5% within 60 days Inventory Accuracy: Target 99%+ across all channels Return Processing Time: Reduce by 50-70% Order Processing Labor: Cut by 30-40 hours monthly Cash Tied in Dead Stock: Reduce by 20-30%

A typical $5M fashion brand sees positive ROI within 4-6 months through reduced oversells and labor savings alone.

Your Next Steps Toward Inventory Excellence

Fixing inventory management isn’t just about avoiding problems—it’s about unlocking growth. When inventory flows seamlessly across channels, when wholesale and retail work in harmony, when returns process automatically, your team can focus on what matters: creating great products and delivering exceptional customer experiences.

The path from inventory chaos to control starts with understanding your specific needs. Every fashion brand’s journey is unique, but the destination is the same: operations that scale efficiently without sacrificing accuracy or margins.

Ready to see how proper inventory stock management software transforms fashion operations? Explore how Blastramp has helped brands process 140,000 Black Friday orders without a hitch, or schedule a demo to discuss your specific inventory challenges. Let’s build an inventory system that grows with your brand, not one that holds it back.